Our Quality

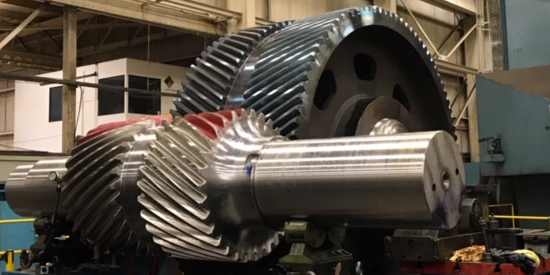

Our uncompromising pursuit of quality and improvement in all processes has positioned Horsburgh & Scott as one of the highest quality designers and manufacturers of industrial gearing and gearboxes in the world.

WE ARE ISO CERTIFIED TO ISO 9001:2015

QUALITY ASSURANCE

Quality-centric individuals and teams have positioned Horsburgh & Scott as one of the highest-quality designers and manufacturers of industrial gearing.

- Engineering analysis and upgrades

- Reverse engineering

- Sophisticated tools and practices to follow rigorous standards, including AGMA, ISO 9001:2015

- Gear cutting (AGMA class 10)

- Gear grinding (AGMA class 14)

- Zeiss Coordinate Measuring Machine (4 x 4 x 2m) within 2 micron accuracy

- Ultrasonic testing (UT), Mag Particle testing (MT), Visual testing (VT), and Penetrant testing (PT)

- On-board lead & involute checking

- Specialized metallurgical testing for heat treat

- Nondestructive testing (NDT)

“We are extremely proud of our commitment to quality. Our ISO certification helps us continually move forward and, equally important, allows us to publicly communicate our dedication to excellence. It’s a symbol that everyone – our employees, our partners, our customers – recognizes and values.”–Randy Burdick, CEO