Gears

Horsburgh & Scott has the expertise to engineer, manufacture, duplicate, replace and repair almost any gear shape, size and make.

High Quality Gearing Solutions

Horsburgh & Scott has the engineering staff and expertise to design a custom gearing solution for your application that will increase productivity and decrease downtime.

We have over 135 years of gear design experience to design a custom gearing solution for your application, or reverse engineer and manufacture your current gearing.

Find Sales Rep or call (216)431-3900

Spur Gears

We have been manufacturing spur gears for 100 years and have the experience to provide you with a gearing solution that will optimize your safety margin, gear strength and performance.

Helical & Double Helical Gears

We can design new custom gears, reverse engineer existing gears and engineer upgrades to improve productivity and life of your helical gearing.

Internal Gears

Our high-quality internal gears reduce sliding action and we have the capabilities to internally grind these gears for optimal performance.

Herringbone Gears

Our herringbone gears are manufactured to have a balanced design that uniformly distributes weight over the shaft bearings, allows the use of identical shaft bearings, and reduces stress on housings and covers.

Shaft / Pinion / Re-shelling

We design and manufacture high-performance pinion / shafts with complex radii and various tapers. Horsburgh & Scott has perfected the process for re-shelling your old integral pinions.

Advantages

- The industry’s most experienced engineers for expert investigation, advice and optimized solutions

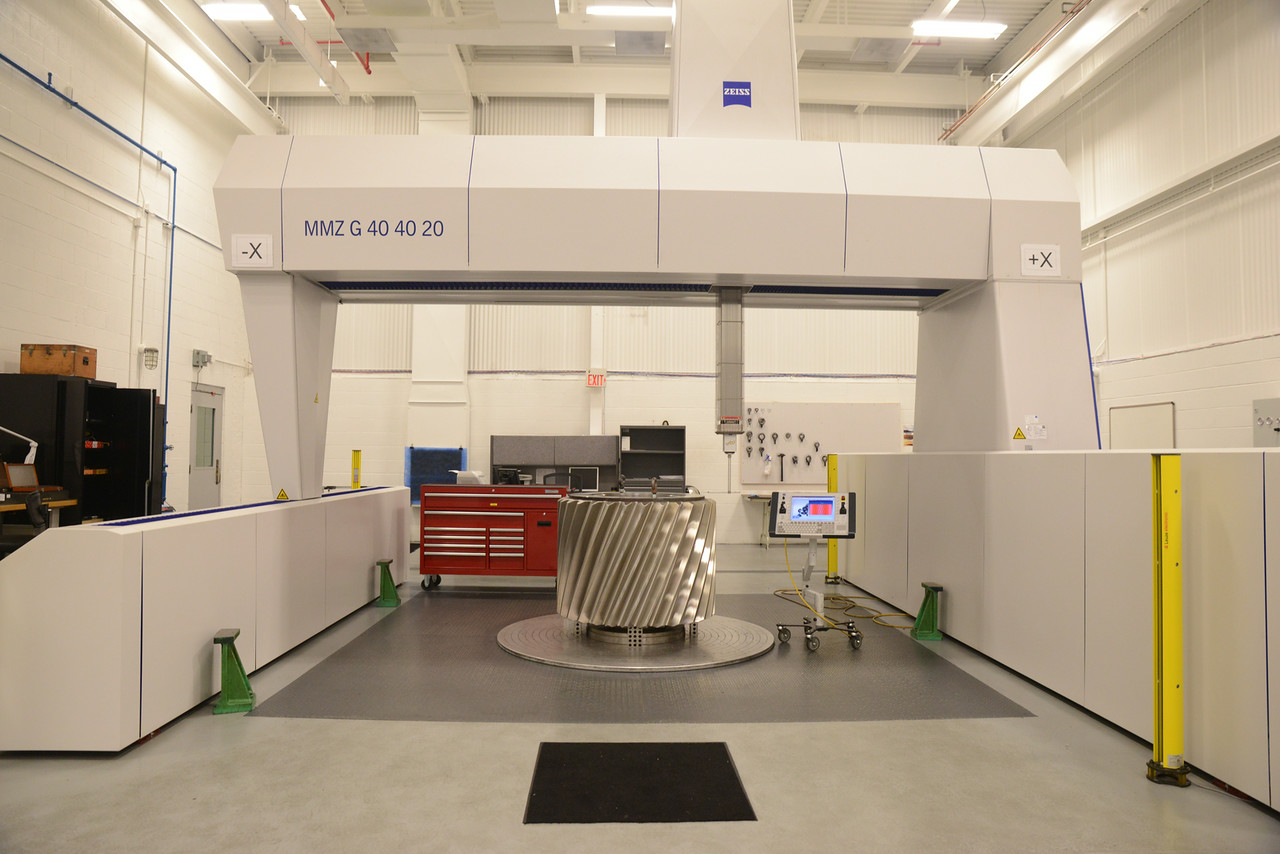

- Capabilities to manufacture small, medium, and large gears

- New gear design, re-engineering, or reverse engineering to increase performance and operating efficiencies

- The highest quality of manufacturing – AGMA, ISO 9001:2018, AASHTO and API

- In-house carburizing and heat treatment for the strongest gears available

- Dependable on-time delivery

Mobile FaroArm