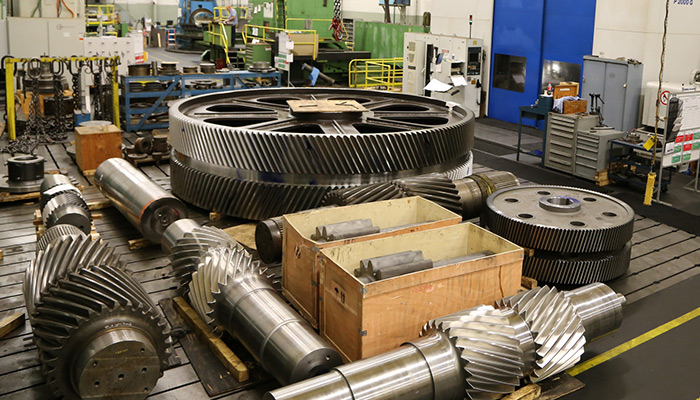

Gearbox Replacement Parts

Horsburgh & Scott offers the best gearbox replacement parts program in the industry. We can save you money by reducing downtime and increasing productivity

Standard and Upgraded Spare Parts for Most Gearboxes

Exact Standard Replacement:

We can provide the exact drop-in part that you need and match any competitive offering.

Standard Replacement Plus:

Enhanced version of the original part for no additional cost. Reduced risk and increased reliability drop-in gearbox replacement part with improved metallurgy.

Upgrade:

Drop-in gearbox replacement part with improved geometry, metallurgy and hardening for increased performance, durability and reliability.

Critical Spare Parts

- Gearing Elements

- Gearbox Components

- Lubrication System Components

- Bearings

- Sub-assemblies

- Gaskets

Find Sales Rep or call (216)431-3900

Advantages

- Review, analyze and recommend a viable spare gearbox parts program

- Existing tooling and drawings for over 100,000 gearbox parts

- Optional drop-in or performance optimized upgrade designs

- On-site gearbox parts installation service upon request

- Expedited emergency gearbox field service, analysis and turn-around time and delivery